Successful projects start with meticulous planning. Our structured approach to the pre-construction process helps our clients make the right decision at the right times.

Not only do our design and fabrication capabilities allow us to continually assess value engineering, “constructability,” and procurement issues – to assure that projects run exactly as planned – they enable us to develop and update budgets and schedules throughout the pre-construction phase.

When it comes to CM at Risk projects, Midstate has a proven track record of maintaining project budget and schedule. Involving Midstate early brings commitment and collaboration from the beginning and creates improved opportunities for cost savings.

More collaboration at an early stage allows the general contractor to be more comfortable in providing a realistic budget to the owner. Midstate Mechanical understands the importance of developing an accurate budget, and we have significant experience serving in this capacity on projects of differing sizes and complexity.

Many projects that don’t have early expertise experience budget overruns, and value engineering is recommended after the fact. This creates rework, adds costs, and often delays construction for redesign.

We are confident that, if brought in early, we can meet or beat the set price. With our proactive approach, Midstate Mechanical can help general contractors and owners meet project budget requirements and deliver the most efficient, cost effective, and highest level of service.

This software provides excellent graphic representation of HVAC, pipe installation drawings and coordination feasibility, all of which helps minimize RFI’s, project delays, and conflicting areas at the beginning stages before construction starts. CAD also verifies the designed mechanical systems physically fit in the architectural and structural confines of the building.

The software consists of Est Duct for estimating, Cadduct/CAD Mechanical for the duct and piping and CadCam for shop fabrication. All are completed in an AutoCAD format for coordination between other trades as well as the structure, and all are tied into the same database for processing through estimating to our shop where it is processed through our coil line/plasma tables for the duct and pipe to our prefabrication shop and finally to our docks for shipping.

We utilize BIM by drawing in 3D and coordinating in 3D to avoid collisions and provide a virtual information model that allows us to work out problems before construction ever begins. BIM can greatly decrease errors and inform team members about parts of the building in conflict or clashing. This error reduction is a great part of the cost savings realized by all members of a project. Reduced time to complete construction directly contributes to the cost savings as well.

Midstate’s unique CAD system allows us to coordinate and pre-plan projects, saving 10-20% of actual field manpower labor. This process can also be accomplished in a short duration, highlights both large problems and small details so they can be addressed during the detailing phase, and affords us the ability to view the installation long before construction begins.

Our design process assures a clean, easily maintained space that is critical to operation and owner satisfaction. The hidden beauty of this system is the automatic generation of material and spool sheets from the finished detailed shop drawings. In the sheet metal division, we can be certain of accurate estimates up front, and can order materials and parts long before fabrication has begun.

Midstates’ fabrication, warehouse, and office facility is located on a 4 1/2 acre site with 58,000 square feet of indoor manufacturing and warehouse space along with additional covered outside fabrication with pre-assembly and staging areas.

Whether the issue is cost savings, job site restrictions, enhanced QA/QC, or the logistics of building design, our clients have benefited from the quality, accuracy, efficiencies, and superior finished installations realized through the use of our fabrication philosophy.

Our sheet metal fabrication facility is equipped with the latest state-of-the-art automated fabrication equipment to include a complete coil line for manufacturing rectangular sections of duct in both lined and unlined sections.

The facilities’ fabrication capacity is well over 3,000,000 pounds of metal duct per year. For comparison, a typical 4-story office building that has a rooftop VAV system would need 100,000 pounds, and a 15-story high rise condo would use about 120,000 pounds.

Our sheet metal fabrication is supported and scheduled through a shared database with our estimating system and CAD (CAM). This database holds our current material prices and productivity rate, so that when a project is drawn in our CAD system, it can be automatically downloaded to our fabrication equipment, producing a labor and material budget.

Midstate Mechanical is the only mechanical contractor in Arizona that is utilizing technology that ties CAD / CAM / Estimating together for manufacturing purposes.

Our sheet metal fabrication facility equipment includes:

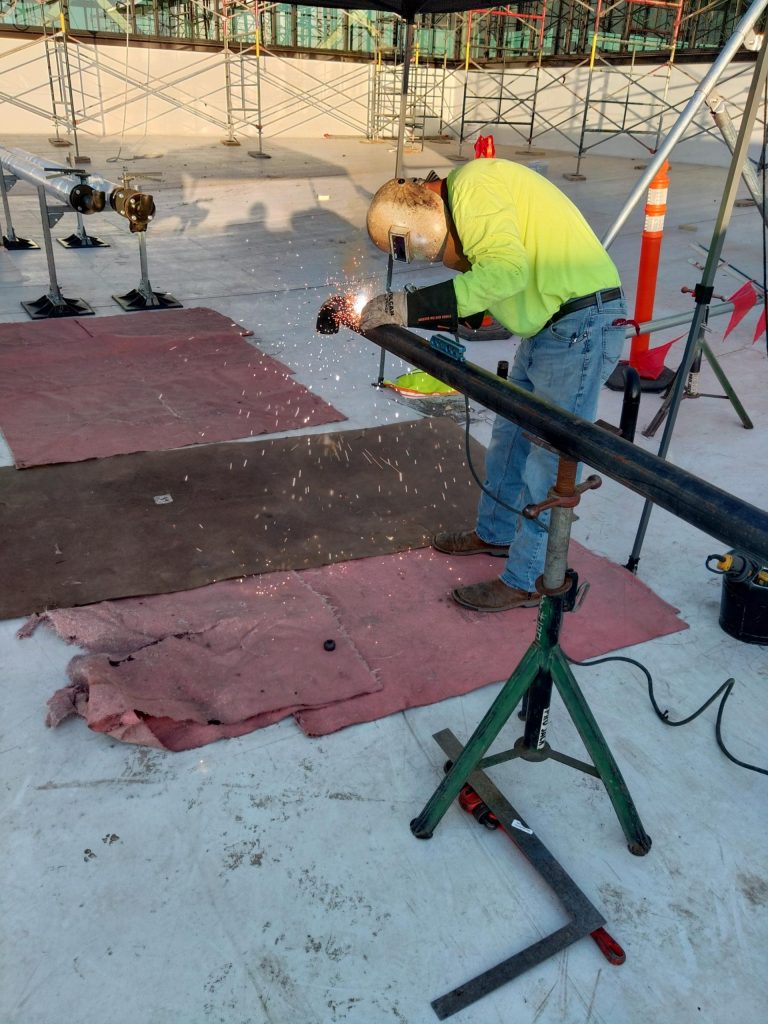

Our plumbing and pipe fabrication is supported with CAM and scheduled through a shared database with our estimating system and CAD.

From our CAD drawings, we are able to produce spool drawings for individual equipment hookups, restroom groups, and other plumbing assemblies. These spool drawings provide a complete list of materials and parts needed, as well as a complete cut list for the pipe that is needed to complete the assembly.

Our pipe shop is equipped with the latest modern cutting and assembly equipment. We can also pre-build and stage complete systems and our assemblies if needed, even before a project breaks ground.